The 3R zero emission/energy independent pyrolysis is an advanced and added value upcycling and reuse of unexploited biomass for recovery of concentrated natural BioPhosphate products. Industrialisation of Refined Carbon & Graphene products.

📌 Quick SummaryTechnology: 3R Zero Emission / Energy Independent Pyrolysis – a scalable deep-tech solution converting unexploited biomass and animal by-products into high-value products. Main Outputs:

Key Advantages:

Technology Highlights:

Global Relevance:

Status:

Ethics & Sustainability:

This summary provides a concise overview of 3R-BioPhosphate Ltd.’s innovative technology. The detailed sections below explore the advanced 3R pyrolysis process, nutrient recovery systems, and sustainable solutions—delivering valuable insights for investors, partners, and stakeholders into 3R’s technological strengths. |

In a world with finite resources there is no infinite development opportunity with sustainability, unless circular economy is not fully implemented. In this context there is no one fit for all processing technology or product solution, but still only the high end solutions are viable and sustainable. The 3R zero emission/energy independent pyrolysis technology provides market competitive and advanced replication model with BAT/BREF (best available technology reference). Recycling of un-exploited biomass resources, such as animal by-products by the advanced 3R pyrolysis technology, generates new resources and market demanded high added value products.

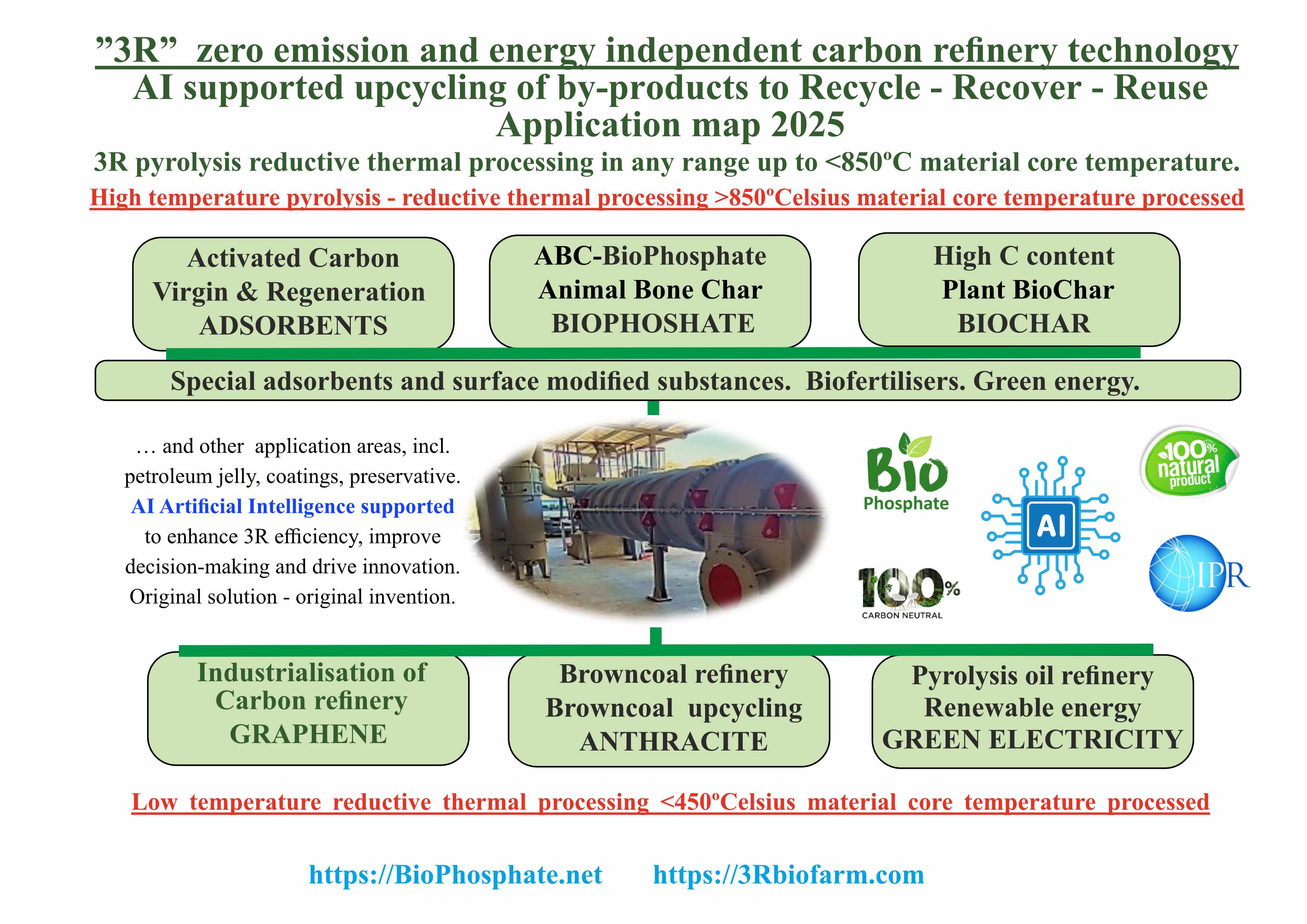

The 3R is an advanced bio-based novel pyrolysis and carbon bio-refinery upcycling technology for recovery of natural BioPhosphate products with zero emission and energy independent circular processing and carbon negative product application performance for high market creating agri and industrial use at less cost.

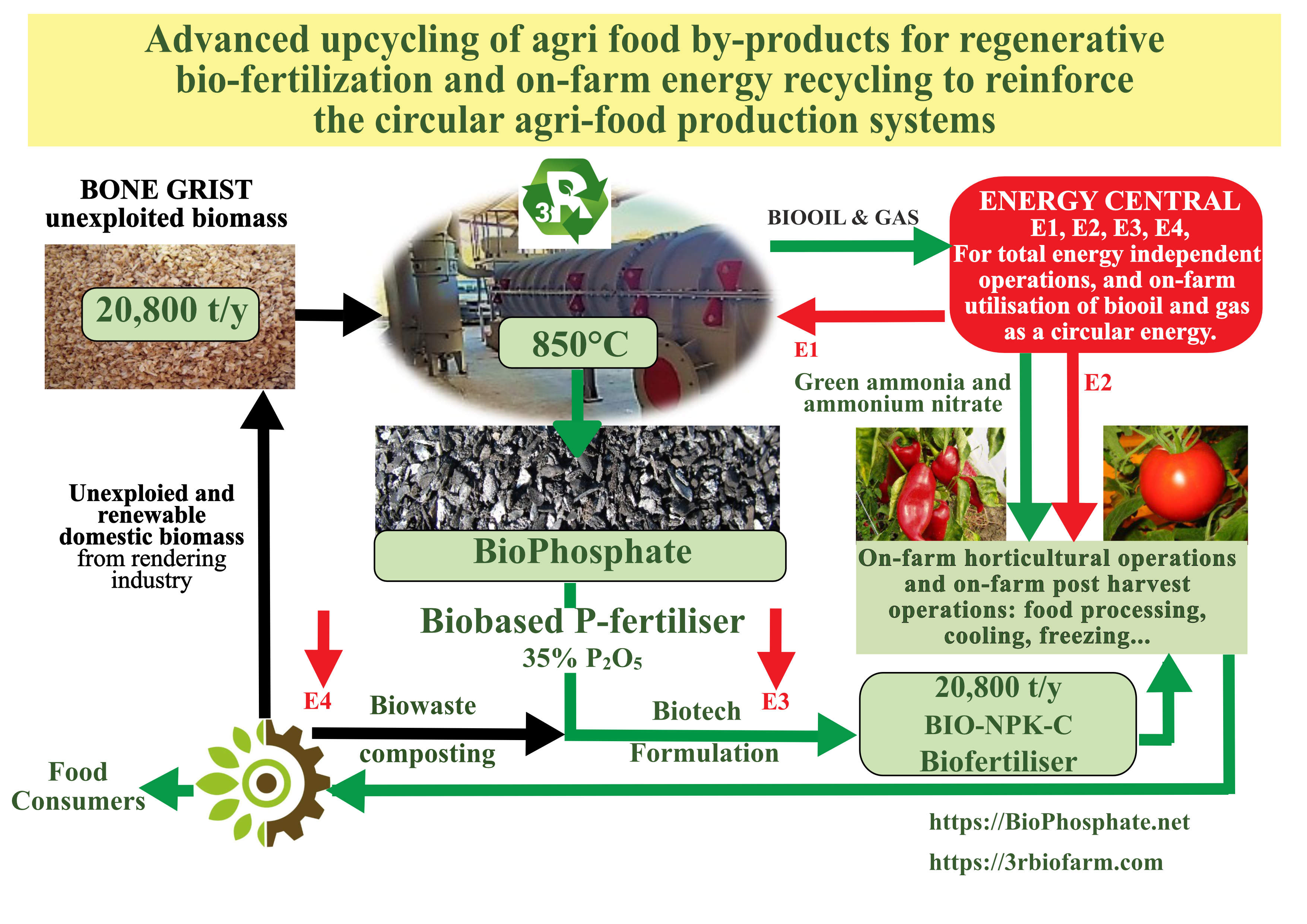

The objective of the 3R ZERO EMISSION PYROLYSIS PROCESS, NUTRIENT RECOVERY AND RESOURCE CONSERVATION technology is the added value upgrading and valorisation of animal by-products into safe and high value recovered organic Phosphorous fertiliser and bio-oil by integrated thermal and biotechnological recycling means.

The 3R zero emission carbon processing and nutrient recovery understands the language of the Mother Nature and takes lessons from Her. The term waste is unknown in the Mother Nature as all and any materials must be re-processed, upcycled and reused in a most efficient way, as simply no any creatures can afford to lose any available resources. Same as the 3R zero emission carbon processing means a total upcycling and reuse of agricultural and food industrial by-product materials, "the resources", for conversion into high added value recovered organic fertiliser and other bioproducts.As a result, the 3R novel processing and upcycling method with innovative products open new technical, economic, environmental and climate solution opportunities, specifically targeted for the temperate climatic zone countries applications in the EU, USA, Australia, Japan and South Korea.

3R Phosphorus recovery process:

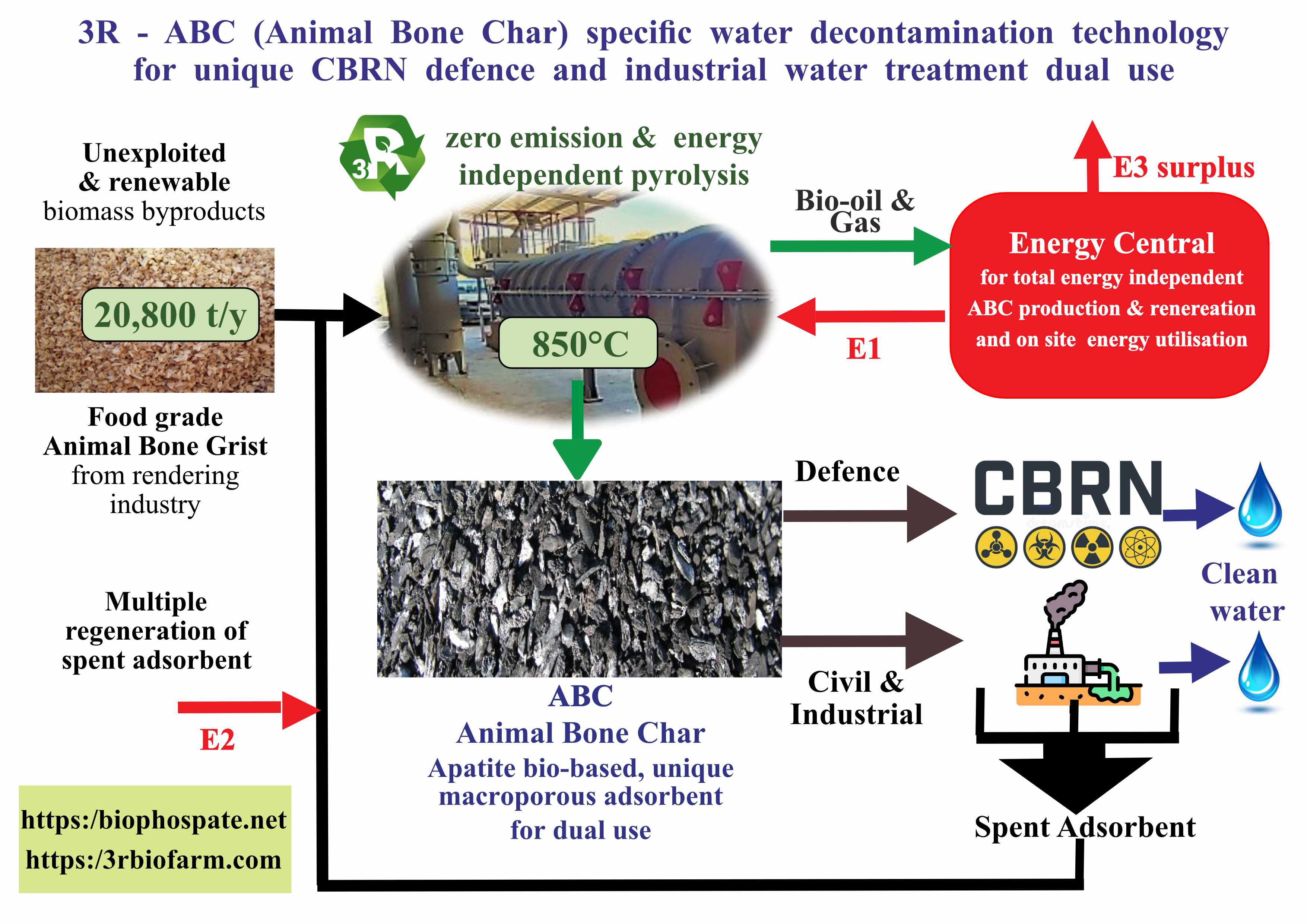

3R water treatment: PREVENT water contamination, PROTECT water resources and RECOVER clan water

3R zero emission technology application map: AI Artificial Intelligence supported upcycling of byproducts

The INPUT FEED STREAMS are low value and unexploited agri/food by-products; including high Phosphorus content food grade (category 3) animal bone grist. Our solution does not incease animal use or animal farming. It valorises unavoidable by-products of existing food systems turning waste into safe, high value inputs that replace fossil-based and contaminant -rich alternatives. The 3R technology platform is feedstock-agnostic and can process both animal-derived and fully plant-based biomass streams.

The OUTPUT PRODUCTS are high quality and safe "ABC" (Animal Bone Char) BioPhosphate or other types of biochar products for wide range of agricultural (recovered natural Phosphorus biofertiliser or soil improver) and environmental (adsorbent) applications.

The specific 3R zero emission pyrolysis and nutrient recovery process is based on a horizontally arranged, indirectly heated revolutionary designed rotary kiln, providing reductive thermal decomposition of any biomass at as high as 850 degree C material core temperature in vacuum. The highly efficient 3R pyrolysis process providing comprehensive upcycling and the reuse of all material and gas feed streams. No any chemicals used.

The output natural products are tested and validated for open ecological soil applications by the Soil and Plant Protection Authority. Moreover the 3R process provides high feed flexibility: it's efficient for carbon and resource conversion both for animal by-products and plant based biomass, suitable for different climatic zone applications. Although it's a complex highly advanced and comprehensive performance, the 3R technology does not contain any exotic technical solutions and materials.

The 3R biomass upcycling offers economic viability, rapid returns, generates new resources, produces high market demanded natural products and low cost green energy. The 3R technology also has a great potential for resource conservation, nutrient recovery and GHG (greenhouse gas) emission reduction as well. The 3R pyrolysis process is a patented original solution and industrial design, its development is priority supported by the EU. The 3R competitive eco-innovative process and operational prototype at high investment readiness level has been successfully demonstrated (3R Pyrolysis Center) regional capacity 2.000 t/y unit.

The new 3R ZERO EMISSION/ENERGY INDEPENDENT pyrolysis process and NUTRIENT RECOVERY technology opening new technical, economical, environmental and climate protection opportunities. In this context the 3R provides high value financial and non-financial benefits for all stakeholders who are receiving extraordinary values from the reached high level and tangible business objectives. The 3R key performance indicators are impressive and replicable but still conservative estimated, including key elements such as:

- Commercial implementation of breakthrough, evidence-based, specialised and innovative technology, which focus on cheapening the value chain by reducing the cost and time of water and agricultural related large infrastructural investments. The project is based on large scale EU Commission co-financed RTD projects I have coordinated and implemented (trusted EU references).

- Targeting social and environmental impacts, such as elimination of contamination from food chain and improvement of food safety for less cost, which impacts are well-defined and integrated into the business model and systematically measured.

- Exceptional team: The management team is experienced and capable with a proven and meaningful track record and focused strategy, able to create sustainable and viable businesses.

- Financial position: The project demonstrating sustainable growth of the business to deliver impact through a promising and realistic business planning, and a significant growth potential at a relatively modest capital investment, with a realistic exit strategy capable of supporting financial and non-financial returns.

Enhanced economy and competitiveness:

- Wide feed and technology flexibility, resulting in a board range of end-products.

- Co-production of refined carbons, biochar products, refined bio-fuels and natural fertilisers (recovered organic Phosphorous and recycled Nitrogen).

- Integrated carbon refinery and nutrient recovery.

- Energy independent.

- AI Artificial Intelligence system concept developed for the TRL9 full industrial applications to enhance and support the unlimited market grow of the original 3R zero emission and energy independent upcycling invention. The AI is aiming to enhance efficiency, improve justified and rapid human decision-making, and further drive the innovation for global commercial production operations

- Advantageous combinations with biogas and composting programmes.

- Low investment and O&M costs with high added value production performance.

- High value financial and non-financial benefits for all stakeholders.

This high added value and multi-functional upcycling transformation of unexploited biomass with solutions for the possible environmental impacts from cradle to grave, resulting greater quality and environmental/climate value of new products with second life and new function that finished product becomes more practical and valuable than what it previously was. The 3R innovative process provides realistic sustainability benefits of the bio-economy, while creating financial and non-financial values and market competitive benefits for all the value chain stakeholders.

The solution follows EU circular economy and waste hierarchy principles by upcycling unavoidable biomass residues, including regulated animal by-products, into safe and sustainable inputs. This approach reduces environmental pressure, replaces imported raw materials, and supports soil regeneration without increasing animal production.

Ethics: We fully respect ethical concerns regarding animal-derived materials. Our approach is strictly based on circular economy principles. Bone char is produced exclusively from unavoidable by-products of the existing food system, classified as waste under EU regulation. Our technology does not incentivise or expand animal agriculture, but reduces environmental impact by replacing imported, contaminant-rich phosphate rock.