📌 Quick Summary

This summary provides a concise overview of 3R innovative product portfolio. The detailed sections below offer in-depth insights into the 3R Bio-Phosphate fertilisers, green adsorbent, renewable energy solutions, and other offerings, showcasing their technical, environmental, and commercial value for investors, partners, and stakeholders. |

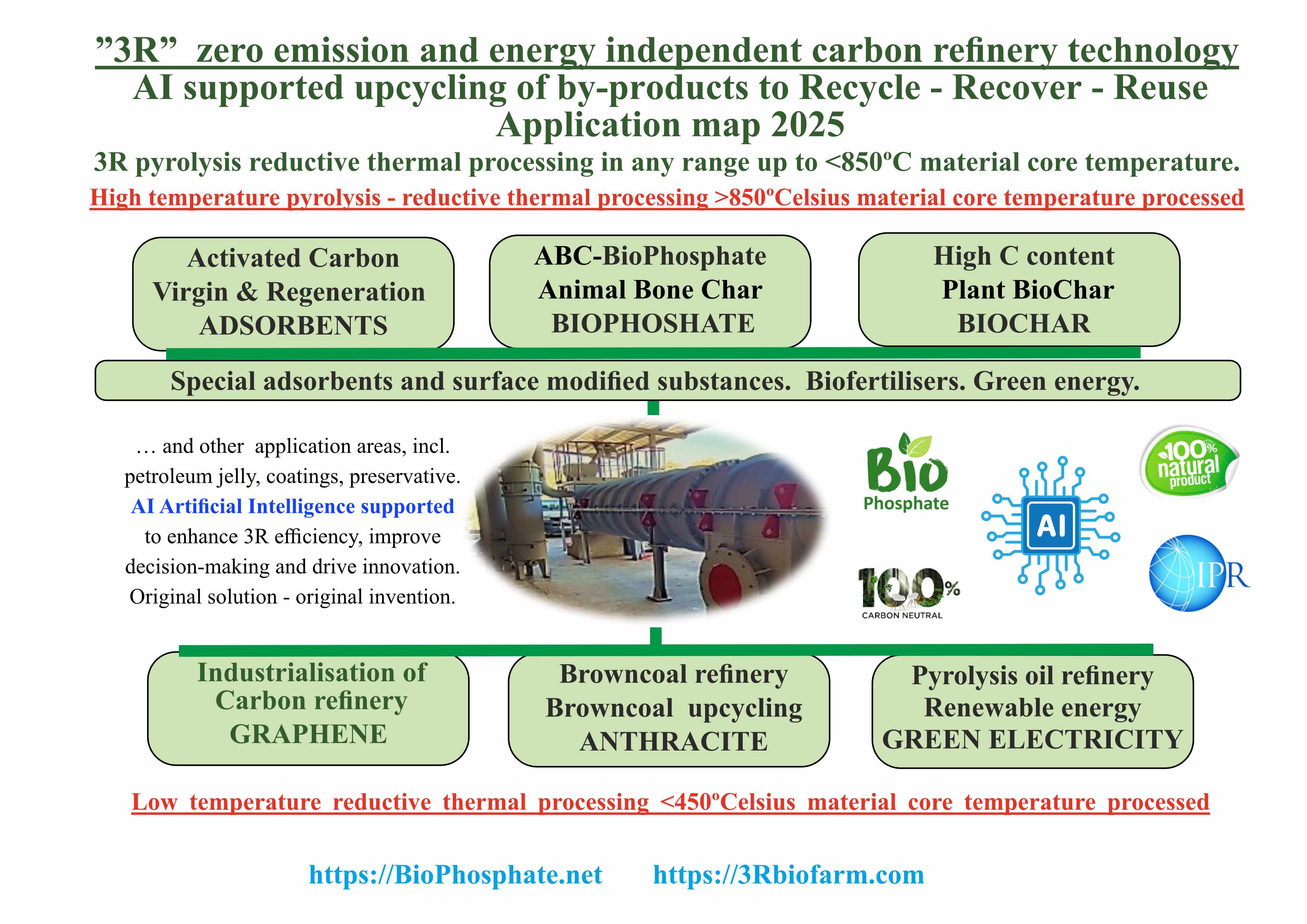

The 3R Industrial Zero Emission Pyrolysis Process delivers a safe, efficient, and climate-positive solution for the transformation of unexploited biomass into high-value outputs, including:

Carbon-negative biochar

Recovered phosphorus fertiliser

Bio-energy products

Additionally, it enables the industrial-scale production of Refined Carbon and Graphene materials, opening new frontiers in advanced materials and clean technology markets.These products, are the carbon negative biochar, recovered phosphorus fertiliser and bio-energy applications.

ABC (Animal Bone Char) BioPhosphate

At the heart of our product line is the ABC (Animal Bone Char) BioPhosphate — a natural, safe, and EU-authorised biofertiliser rich in Phosphorus (>35% total P as P₂O₅). It serves as a powerful plant growth promoter with multiple agronomic benefits, especially for organic and low-input farming systems. The input feedstock is strategically selected based on economic goals, logistics, and availability. For maximum phosphorus recovery, food-grade animal bone is used as the mono feedstock.

Certified, Compliant & Ready for Market:

EU Authority-permitted for both the 3R Zero Emission Pyrolysis Process and ABC BioPhosphate use in open ecological soil environments

Horticultural application permit: 6300/13393-2/2019, issued under EU Regulation 2019/515, valid since April 19, 2020

EU REACH registered for industrial scale production (>1000 tonnes/year)

REACH Registration Number: 01-2119490075-38-0042

Proven Performance Across Europe. The effectiveness of BioPhosphate has been validated through open-field and greenhouse trials in multiple EU countries:

🇩🇪 Germany | 🇳🇱 Netherlands | 🇮🇹 Italy | 🇮🇱 Israel | 🇭🇺 Hungary | 🇸🇮 Slovenia | 🇩🇰 Denmark

under varied temperate climates and soil types.

Please visit our specific biofertilisers website

3R Water treatment adsorbent applications: PREVENT water contamibation, PROTECT water resources and RECOVER clean water

The ABC Animal Bone Char (BioPhosphate) adsorbent is a high-performance, natural filtration material, composed of approximately 92% calcium phosphate bio-apatite and 8% carbon. It features a fully macroporous structure with unique external and internal surface properties, created through the innovative 3R zero-emission carbon refinery process, which applies high core temperatures while maintaining environmental sustainability.

Thanks to these advanced characteristics, the ABC adsorbent demonstrates exceptional efficiency and reliability across a wide range of filtration and purification applications, such as:

- Drinking water treatment – safe and effective removal of impurities, ensuring clean and healthy water.

- Food industry process water cleaning – improving water quality to meet strict hygiene and safety standards.

- Removal of potentially toxic elements (PTEs) – such as heavy metals, fluoride, arsenic, and other contaminants from different water streams.

- Industrial wastewater treatment – reducing pollutants and supporting compliance with environmental regulations.

- Military and defense applications – reliable adsorbent for field water purification and decontamination systems, ensuring operational safety in challenging environments.

- Nuclear contamination control – effective in the adsorption and removal of radioactive isotopes and nuclear pollutants from water, supporting remediation and environmental safety efforts.

- Circular economy applications – recovering valuable nutrients and supporting sustainable resource management.

Each application is evaluated case by case to determine the most suitable BioPhosphate grade, ensuring optimized performance, cost-effectiveness, and safe, sustainable results for our partners.

Please visit our specific adsorbents website

3R BIOFUEL: Green Energy from pyrolysis Oils

The 3R zero-emission pyrolysis process not only recovers valuable materials but also produces non-condensable gases and crude bio-oils as secondary outputs. These energy-rich by-products can be further upgraded through advanced refining and co-processing technologies to generate a broad spectrum of high-quality biofuels—including bio-diesel, bio-kerosene, and synthetic fuels—as well as renewable green electricity.

A key advantage of the 3R system lies in its auto-thermal operation, meaning it functions without the need for any external energy input. Instead, the process is self-sustaining and highly efficient, while simultaneously generating a surplus of renewable energy. This surplus green power can be fed back into the grid or directly utilized on-site, contributing to:

- Carbon-neutral energy production – replacing fossil fuels with renewable, sustainable alternatives.

- Grid decarbonization – stabilizing and strengthening renewable energy supply.

- Energy independence – reducing reliance on imported fossil resources and enhancing local energy security.

- Circular economy integration – transforming organic residues and by-products into high-value energy carriers.

- Military and strategic applications – providing secure, decentralized, and renewable energy sources in critical environments.

By coupling biofuel generation with green electricity production, the 3R technology delivers a dual environmental and economic impact, enabling partners to meet strict climate goals while unlocking new revenue streams from renewable energy markets.

Graphene products -Unlocking the Future of Carbon Nanomaterials:

Graphene is a revolutionary carbon-based nanomaterial and a unique allotrope of carbon, consisting of a single layer of tightly bonded atoms arranged in a two-dimensional hexagonal lattice. This extraordinary structure makes graphene:

200 times stronger than steel

Capable of stretching up to 25% of its original length

More electrically conductive than copper

Known for exceptionally high electron mobility

These properties position graphene as a breakthrough material for next-generation electronics and other advanced applications.

However, despite extensive laboratory-scale research, the industrial production of large, high-quality graphene sheets remains a major challenge. At 3R, our focus is on overcoming this barrier by advancing the commercial-scale industrialisation of graphene, paving the way for its widespread commercial use.Graphene is an allotrope (different form) of carbon and carbon-based nanomaterial, which is consisting of a single layer of atoms that are tightly bonded carbon atoms, arranged in a two-dimensional honeycomb hexagonal lattice. This unique material is 200x stronger than steel, can stretch up to 25% of its original length and more electrically conductive than Copper. Graphene is a material of interest due to its high electron mobility and its possible applications in electronics. However, while graphene has been wide range researched in laboratory scale and it may be easy to isolate this one atom thick material in laboratory, but it is difficult to industrialise and produce large sheets for commercial use. Our graphene research objective is the commercial scale industrialisation of this new material.

Ethics: We fully respect ethical concerns regarding animal-derived materials. Our approach is strictly based on circular economy principles. Bone char is produced exclusively from unavoidable by-products of the existing food system, classified as waste under EU regulation. Our technology does not incentivise or expand animal agriculture, but reduces environmental impact by replacing imported, contaminant-rich phosphate rock.

The solution follows EU circular economy and waste hierarchy principles by upcycling unavoidable biomass residues, including regulated animal by-products, into safe and sustainable inputs. This approach reduces environmental pressure, replaces imported raw materials, and supports soil regeneration without increasing animal production.